FROM CONCEPT TO CREATION: EXCELLENCE ENGINEERING IN ELASTOMERS.

ONE STOP DESTINATION FOR ALL YOUR ENGINEERING SOLUTIONS.

OUR ETHOS

VISION

MISSION

VALUE

PRODUCTS PORTFOLIO

LEVERAGE OUR CAPABILITIES

OUR SERVICES

Polyurethane Casting

TPE - Injection Molding

Tools & Mold development

Customization

Product Design &

Engineering

Static & Dynamic

Testing

Dynamic Mechanical

Analysis

Material

Selection

WHAT'S HAPPENING

Checkout what we have been doing

WHAT ARE THE THINGS TO CONSIDER BEFORE MACHINING URETHANE MATERIAL?

THE MINING INDUSTRY AND URETHANE PARTS: THE PERFECT UNION

BENEFITS OF USING POLYURETHANE IN OIL & GAS DRILLING.

STAY AHEAD, BECAUSE WE ARE.

developments in subjects like technology, sustainability, safety and health, and evolving statutory regulations.

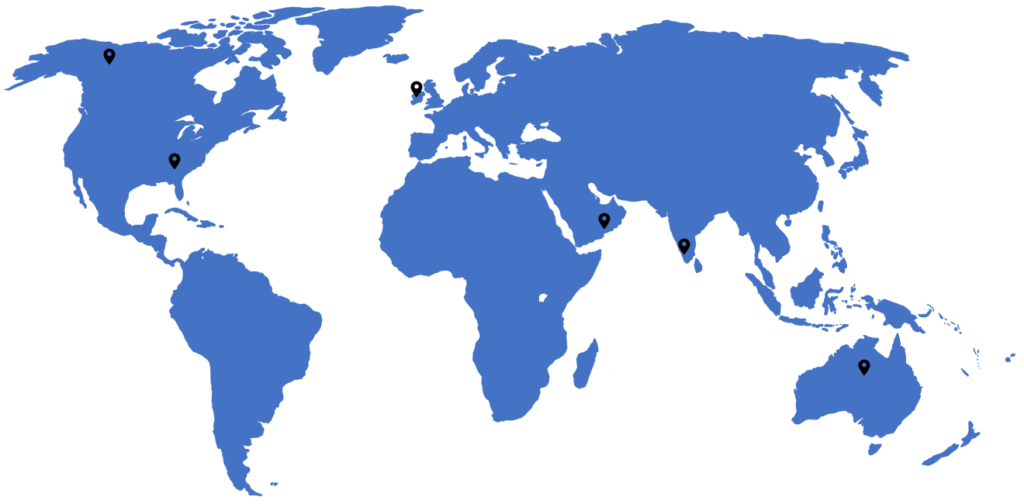

TRUSTED BY

EXPORT COUNTRIES

- United States

- Germany

- Middle East

- Australia

- Bangladesh

- Sri Lanka

HOW ABOUT FACETIME..

Polyurethane offers versatility not only in its physical properties but also in its aesthetic appeal, including colour options. PU can be manufactured in a wide range of colours, from vibrant hues to subtle shades, depending on the specific requirements of the application or customer preference. This flexibility makes PU suitable for diverse industries such as furniture, automotive interiors, footwear, and consumer goods where colour plays a crucial role in product design and branding. The ability to customize the colour of polyurethane is achieved through the incorporation of pigments or dyes during the manufacturing process. This allows manufacturers to match specific colour standards, meet design specifications, or create unique finishes that enhance the visual appeal of products. Whether it’s creating eye-catching furniture upholstery, stylish footwear, or coordinated automotive interiors, polyurethane’s colour customization capability adds a dimension of creativity and aesthetic appeal, making it a preferred choice in industries where both functionality and visual impact are key considerations.

Polyurethane is well-regarded for its ability to withstand varying loads and stresses, making it a versatile choice in applications requiring durability and resilience under pressure. PU’s molecular structure and elastomeric properties allow it to distribute and absorb load efficiently, making it suitable for load-bearing components such as wheels, bushings, springs, and industrial mounts. This property ensures that PU can withstand heavy loads without permanent deformation, maintaining structural integrity and performance over extended periods. In industries ranging from automotive and aerospace to construction and manufacturing, polyurethane’s ability to handle diverse load applications is highly valued. Engineers select PU for its strength-to-weight ratio and ability to endure dynamic loads, providing reliable support and reducing the risk of mechanical failure. By optimizing formulations and design configurations, manufacturers can tailor PU products to meet specific load requirements, ensuring robust performance in demanding environments where reliability and longevity are paramount concerns.

Polyurethane (PU) exhibits excellent dimensional stability, which refers to its ability to maintain its shape and size over time and under varying environmental conditions. PU’s molecular structure and cross-linking capabilities contribute to this property, ensuring that products retain their intended dimensions without significant shrinkage, expansion, or deformation. This dimensional stability is crucial in industries such as automotive manufacturing, where precision components like seals, gaskets, and bushings must maintain tight tolerances to ensure proper fit and functionality. Engineers and designers rely on polyurethane for its predictable dimensional behavior, allowing for accurate and consistent manufacturing processes. Whether in injection molding, casting, or extrusion applications, PU’s dimensional stability helps to achieve high-quality end products that meet stringent specifications and performance requirements. This reliability in maintaining dimensions also extends to consumer goods like furniture and electronics, where PU components contribute to seamless assembly and reliable performance throughout the product’s lifecycle.

Polyurethane exhibits excellent bonding properties, allowing it to adhere strongly to a wide variety of substrates including metals, plastics, wood, and textiles. PU’s ability to form strong bonds is attributed to its chemical structure, which includes reactive functional groups that can undergo cross-linking and polymerization reactions with substrate surfaces. This property is particularly advantageous in manufacturing processes where reliable adhesion is essential for the assembly of complex components and structures. Engineers and manufacturers value polyurethane for its versatility in bonding applications, whether in automotive parts, footwear, furniture, or construction materials. PU adhesives and sealants are widely used to bond different materials together effectively, providing durable and resilient connections that withstand environmental stresses and mechanical loads. By optimizing formulations and application techniques, PU can achieve robust bonding strength, contributing to enhanced product performance, longevity, and overall quality in various industrial and consumer applications.

Hysteresis is an important property of polyurethane that describes its ability to dissipate energy as heat when subjected to cyclic loading and unloading. PU’s viscoelastic nature allows it to absorb mechanical energy during deformation and release it as heat upon recovery, resulting in a loss of energy in the form of hysteresis. This property is significant in applications where damping and energy absorption are critical, such as in shock absorbers, cushioning materials, and vibration isolation mounts. Engineers and designers leverage PU’s hysteresis characteristics to improve the performance and efficiency of products by reducing vibrations and minimizing the impact of repetitive forces. By selecting PU formulations that exhibit controlled hysteresis, manufacturers can enhance the material’s ability to provide comfort, stability, and durability in various applications. This makes polyurethane a versatile choice in industries where the mitigation of mechanical energy and the optimization of performance are essential considerations for achieving reliable and long-lasting product solutions.

Fatigue resistance is a critical property of polyurethane that characterizes its ability to withstand repeated cyclic loading without experiencing permanent deformation or failure. PU’s molecular structure and viscoelastic nature enable it to dissipate energy efficiently, thereby reducing the accumulation of stress that can lead to fatigue failure over time. This property makes PU well-suited for applications where components are subjected to continuous or intermittent dynamic loading, such as in automotive suspension systems, industrial machinery, and athletic equipment. Engineers and designers rely on polyurethane for its superior fatigue resistance, which helps to extend the operational life of products and reduce maintenance costs. By selecting PU formulations with optimized resilience and elasticity, manufacturers can enhance the material’s ability to endure prolonged use under varying stress conditions. This reliability in fatigue performance ensures that PU remains a preferred choice in industries requiring durable materials capable of withstanding the rigors of cyclic loading and ensuring long-term operational efficiency and safety.

Polyurethane boasts impressive tensile strength, which is a measure of its ability to withstand stretching or pulling forces without breaking or deforming permanently. PU’s molecular structure and the cross-linking of its polymer chains contribute to its high tensile strength, making it suitable for applications where materials need to endure significant mechanical stress. This property is crucial in industries such as automotive, aerospace, construction, and manufacturing, where components like belts, hoses, seals, and structural elements require robust tensile properties to ensure reliability and safety. Engineers and designers appreciate polyurethane for its balanced combination of flexibility and strength, allowing it to withstand varying loads and conditions without compromising performance. By adjusting the formulation and processing techniques, PU can be tailored to achieve specific tensile strength requirements, optimizing its suitability for diverse applications. Whether it’s supporting heavy loads in industrial equipment or withstanding dynamic forces in athletic gear, polyurethane’s exceptional tensile strength contributes to its widespread use across industries seeking durable and resilient materials.

Polyurethane exhibits exceptional abrasion resistance, making it highly suitable for applications where materials are subjected to wear and friction over time. PU’s resistance to abrasion is attributed to its durable molecular structure and the ability to withstand mechanical wear without significant deterioration. This property is particularly advantageous in industries such as mining, construction, manufacturing, and automotive, where components like wheels, seals, liners, and conveyor belts require robust resistance to abrasion to ensure prolonged operational life and reduced maintenance costs. Engineers and designers value polyurethane for its ability to maintain its integrity and surface finish even under harsh abrasive conditions. By choosing formulations with optimized hardness and additives, PU can be tailored to withstand specific levels of abrasion, enhancing its suitability for a wide range of industrial and commercial applications. Whether in heavy-duty machinery components or everyday consumer products, polyurethane’s superior abrasion resistance contributes to enhanced performance, longevity, and overall reliability in demanding environments.

Polyurethane exhibits excellent damping properties, which are critical in reducing vibrations, noise, and impacts in various applications. PU’s ability to absorb and dissipate energy efficiently stems from its viscoelastic nature and molecular structure, which allows it to transform mechanical energy into heat. This property makes PU ideal for use in products such as shock absorbers, vibration dampers, and noise isolation mounts where minimizing oscillations and vibrations is essential for smooth operation and enhanced comfort. Engineers and designers value polyurethane for its damping capabilities because it helps improve the performance and longevity of products by reducing wear and fatigue caused by repetitive impacts or vibrations. In industries ranging from automotive and aerospace to consumer electronics and construction, PU’s damping properties contribute to safer and quieter environments while enhancing overall product reliability. By attenuating vibrations and dampening noise effectively, polyurethane plays a crucial role in enhancing user experience and maintaining operational efficiency across diverse applications.

The coefficient of friction is an important property that determines its ability to resist sliding or slipping against other surfaces. PU exhibits a moderate coefficient of friction, which can be adjusted based on the specific formulation and additives used during production. This property is crucial in applications where controlled movement, grip, or frictional resistance is necessary, such as in conveyor belts, drive belts, seals, and various industrial and consumer products. PU’s coefficient of friction helps ensure stable and predictable performance, whether it’s providing traction in footwear soles or facilitating smooth operation in mechanical components.Engineers often manipulate the coefficient of friction of polyurethane through additives or surface treatments to optimize performance for specific applications. For instance, in automotive applications, PU components like bushings and bearings benefit from a carefully balanced coefficient of friction to enhance handling and minimize wear. Similarly, in packaging machinery, PU’s frictional properties contribute to efficient product handling and packaging processes. The controllable nature of PU’s coefficient of friction makes it a versatile material choice, capable of meeting diverse performance requirements across various industries and applications.

Resilience is a property of polyurethane that highlights its ability to return to its original shape after being compressed or deformed. This characteristic is integral to PU’s performance in applications requiring cushioning, shock absorption, and support over repeated use. PU’s molecular structure and elastomeric properties allow it to withstand compression forces without permanent deformation, ensuring durability and maintaining consistent performance over time. This resilience makes PU suitable for diverse applications, including mattresses, automotive components, athletic footwear, and seals, where the material needs to retain its shape and functionality under varying loads and conditions. Engineers and designers value polyurethane for its resilience because it enhances the longevity and reliability of products. By efficiently absorbing energy and distributing stress, PU helps to reduce wear and tear, thereby extending the lifespan of components and improving overall user comfort and safety. The ability of polyurethane to bounce back from compression and maintain its resilience over extended periods makes it a versatile choice in industries where performance under pressure and durability are critical considerations.

Polyurethane exhibits a notable property known as bulk modulus, which refers to its ability to resist compression under uniform pressure. This property is crucial in applications where materials need to absorb and dampen shocks and vibrations effectively. PU’s high bulk modulus allows it to deform elastically when subjected to pressure and return to its original shape once the pressure is released, making it ideal for applications requiring resilience and cushioning, such as in shock absorbers, footwear soles, and damping pads. The bulk modulus of polyurethane can be tailored through adjustments in its formulation and processing techniques, enabling engineers to fine-tune its elasticity and damping characteristics for specific applications. This versatility makes PU a preferred material in industries where impact resistance and vibration damping are critical for enhancing product performance and durability. Whether in automotive suspensions, industrial machinery mounts, or ergonomic seating, polyurethane’s ability to absorb energy and resist permanent deformation due to its bulk modulus contributes significantly to its widespread use across various sectors.

Polyurethane exhibits varying degrees of flame resistance depending on its formulation and additives. While pure PU foam is generally combustible, additives such as flame retardants can be incorporated to enhance its resistance to ignition and combustion. These additives work by suppressing the formation of flammable gases and slowing down the spread of flames, thereby increasing the material’s fire safety characteristics. In applications where fire safety is a concern, such as in building materials, automotive interiors, and upholstered furniture, flame-retardant polyurethane formulations are used to meet stringent safety standards. These formulations help minimize the risk of fire propagation and reduce the release of toxic gases in the event of a fire, enhancing overall safety for occupants and minimizing property damage. PU’s ability to be tailored for specific fire resistance requirements makes it a versatile choice for applications where both performance and safety are paramount concerns.

Polyurethane exhibits a wide temperature range capability varying from -50 degree to 170 degrees Celsius, making it suitable for applications spanning from extreme cold to elevated heat conditions. PU’s flexibility in temperature performance is attributed to its molecular structure and the ability to adjust its formulation to meet specific thermal requirements. This property ensures that PU maintains its mechanical properties, such as flexibility and strength, across a broad spectrum of temperatures, which is crucial for diverse industrial and consumer applications. In cold environments, polyurethane remains flexible and resilient, making it ideal for use in automotive components like seals and bushings, where performance under freezing conditions is essential. Conversely, PU can also withstand high temperatures without significant degradation, which is advantageous in applications such as industrial rollers, where exposure to heat is common. Engineers and designers often leverage PU’s temperature range capabilities to create products that offer consistent performance across varying environmental conditions, ensuring durability and reliability in challenging operational settings.

Polyurethane is valued for its excellent chemical resistance, which allows it to withstand exposure to a wide range of chemicals without significant degradation. This property is particularly advantageous in industries such as automotive, construction, and chemical processing, where materials must endure exposure to oils, solvents, acids, and other corrosive substances. PU’s molecular structure and cross-linking provide a barrier that prevents chemical penetration and maintains its mechanical properties over time, ensuring long-term reliability and performance. The chemical resistance of polyurethane can be further enhanced through formulation adjustments and additives tailored to specific environmental conditions. This versatility allows PU to be customized for applications where resistance to particular chemicals is critical. For instance, in conveyor belts used in mining operations or seals in chemical processing equipment, PU’s ability to resist chemical attack helps to extend service life and minimize maintenance requirements. Overall, polyurethane’s robust chemical resistance makes it a preferred material choice in environments where exposure to harsh chemicals is common and reliability is paramount.

Compression set is a critical property of polyurethane that measures its ability to recover its original shape after being subjected to compression over time. PU exhibits excellent resistance to compression set due to its elastomeric nature and molecular structure, which allows it to maintain dimensional stability and performance integrity even under prolonged pressure. This property is particularly advantageous in applications where seals, gaskets, and other components must maintain a tight seal or consistent mechanical function over extended periods.The low compression set of polyurethane translates into enhanced reliability and durability in various industries. For example, in automotive applications, PU components such as suspension bushings and seals need to withstand constant compression and vibration without losing their shape or functionality. Similarly, in furniture and bedding, PU foams with low compression set ensure long-lasting comfort and support. Engineers and designers often favor polyurethane for its ability to resist permanent deformation, ensuring that products maintain their intended performance characteristics throughout their lifespan.

Tear strength measures the resistance of a material to tearing forces and is crucial in products subjected to mechanical stress or wear. PU’s molecular structure and bonding give it superior tear resistance compared to many other elastomers and plastics, making it highly durable in demanding environments. This property makes PU ideal for applications such as seals, gaskets, conveyor belts, and protective clothing where resistance to tearing is essential for longevity and performance. In addition to its inherent tear resistance, polyurethane can be formulated to meet specific tear strength requirements through adjustments in its chemical composition and manufacturing process. This versatility allows engineers and designers to tailor PU products to withstand varying levels of mechanical strain, ensuring reliability and longevity in diverse applications. Whether in industrial machinery components or athletic equipment, polyurethane’s exceptional tear strength contributes significantly to its reputation as a robust and reliable material choice across a wide range of industries.

Hardness is measured via overlapping scales: Shore A and Shore D, and in some cases Shore OO or Rockwell R. To measure Shore hardness, a durometer is used, which presses a needle-like rod into the material’s surface to measure the depth of indentation. For example, polyurethane elastomers may have Shore A hardness values ranging from very soft (Shore A 20) to quite hard (Shore A 90+). On the other hand, rigid polyurethane foams used in insulation or structural applications may have much higher hardness values, often measured on the Shore D scale. The hardness of a specific polyurethane material is determined by factors such as the types and proportions of the polyols and isocyanates used in its synthesis, as well as any additives or fillers included in the formulation. Many applications – from shock absorbers to wheels to wear pads – take advantage of polyurethane’s unique combinations of performance and hardness. Polyurethane durometer is another way of saying polyurethane hardness.

The modulus of elasticity, often referred to simply as the modulus, is a measure of a material’s stiffness or its ability to deform under stress. Polyurethane materials can have a wide range of moduli depending on their formulation and intended application. For polyurethane elastomers, which are typically flexible and rubber-like materials, the modulus of elasticity can vary depending on factors such as the type and concentration of polyols, isocyanates, and any additives used in the formulation. These materials often have relatively low moduli compared to rigid plastics. The modulus of elasticity for a specific polyurethane material can be determined through testing methods such as tensile testing or compression testing, where the material’s response to applied stress is measured. The modulus is typically reported in units such as Pascals (Pa) or pounds per square inch (psi).