HELPING YOU DESIGN THE PERFECT PRODUCT

Polyurethane is a unique and versatile material because it acts like rubber, plastic, and polymer, which

means it offers stellar performance across a wide range of applications.

Depending on your particular needs, the chemical formula and process can be customized to your specific

application. Whether your use calls for something flexible and durable, or whether you need something

rigid, polyurethane is the answer to thousands of engineering problems.

Here are a few of polyurethane’s highlights:

- More resistant to wear than other materials

- Has superb load bearing capacity and resists impact better than metal or plastic

- Easily molds into complex shapes depending on the need

Whatever the application, we can engineer the polyurethane component to meet that need. This design

guide highlights the many customization options available to you to help better find what’s right for your

specific needs.

HOW DOES POLYURETHANE COMPARE TO OTHER MATERIALS?

Versus Rubber, Polyurethane has

Better:

- Abrasion Resistance

- Cut and Tear Resistance

- Load-Bearing Capability

- Wear Life

Potential For:

- Abrasion Resistance

- Cut and Tear Resistance

- Load-Bearing Capability

- Wear Life

Versus Plastic, Polyurethane has

Better:

- Abrasion Resistance

- Load-Bearing Capability

- Impact Resistance

- Elastic Memory

- Resilience

- Compression Set Resistance

- Low Operating Temperature

Potential For:

- Complex Shapes with Thin and Thick Sections

- A variable Coefficient of Friction

- Noise Reduction

- Lower Cost, Low-Pressure Tooling

Versus Metal, Polyurethane has

Better:

- Abrasion Resistance

- Impact Resistance

- Flexibility

- Resilience

- Corrosion Resistance

Potential For:

- Weight Reduction

- Non-Conductive

- Non-Sparking

- Noise Reduction

- Lower Cost Molding vs. Metal Machining

- Lower Product Cost

WE ENGINEER THE POLYURETHANE TO BEST SUIT YOUR APPLICATION. WHAT PERFORMANCE PROPERTIES ARE IMPORTANT TO YOU?

MODULUS OF ELASTICITY

HARDNESS

TEAR STRENGTH

COMPRESSION SET

CHEMICAL RESISTANCE

TEMPERATURE RANGE

FLAME RESISTANCE

BULK MODULUS

RESILIENCE / REBOUND

COEFFICIENT OF FRICTION

DAMPENING

COLOR

ABRASION RESISTANCE

TENSILE STRENGTH

THERE IS EVEN MORE TO CONSIDER FOR YOUR DESIGN

Fatigue

Hysteresis

Bonding

Dimensional Tolerances

Load

Application

CALCULATING THE COMPRESSION/DEFLECTION OF URETHANE

Polyurethane, unlike rubber, is a non-compressible elastomer, meaning its volume will not change. In other words if you squeeze it in one place, it will bulge the same amount in

another place. For that reason, it makes an excellent material for load-bearing applications.

In load-bearing applications such as isolation pads, bumpers, bushings, rollers and wheels, it is important to know the amount of deflection the part will have when under load. For

most applications a range between 5% to 15% deflection is acceptable. However, applications with rapid continuous deflection may need to be limited to lower deflection

percentages. We recommend not exceeding 25% deflection regardless of the application.

FACTORS THAT DETERMINE THE AMOUNT OF DEFLECTION

- Hardness(durometer) of the polyurethane

- Shape of the part

- Amount of load placed on the part

- Condition of the part’s loaded surface

Although the formula for calculating compression/deflection was scientifically derived, the many variables involved can make it difficult to precisely predit the outcome. The formula

used in example 1 is for pads or cylindrically shaped bumpers only.

Two Imnortant Concidoratione Whon Calculatina Comnroccion/NofloctionI

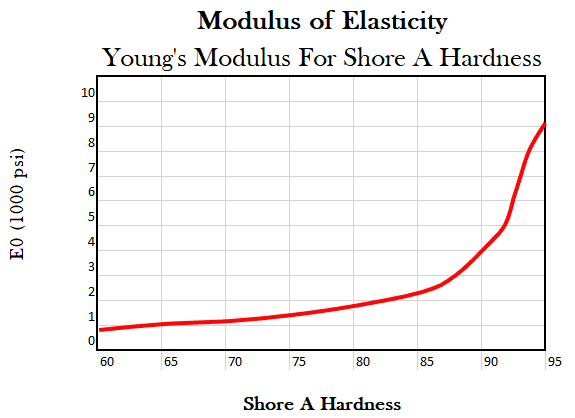

Polyurethanes heat up in dynamic applications which can lower the durometer and in turn, will lower the Young’s modulus.

There can be a very large difference in compression/deflection between a part with bonded surfaces, versus the same part between lubricated surfaces. Compression/deflection values

for parts compressed between surfaces that are neither bonded nor lubricated, cannot be accurately calculated.

Example 1 - Pads

You have a 92A durometer(hardness) isolation pad that is 6″ long by 3″ wide and 2″ thick, that is under a

3,600 lb load. You want to know how much deflection it will have.

The formula is: L=D x Y x (1+2f2)

D = % of deflection/inch of thickness

L = load or force in psi

Y = Young’s Modulus (see Modulus of Elasticity Diagram below)

f = shape factor

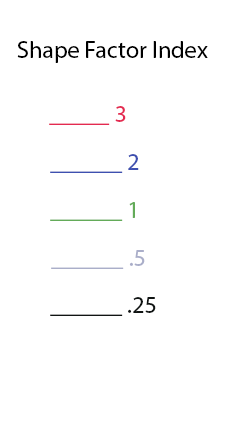

*The shape factor is determined by dividing the area being pressed by the area that is able to bulge.

Solution To Example 1

L = 3600 lbs ÷ 18 square inches (6 x 3) = 200 psi

Y = 4500 psi for 92A durometer(hardness)

f = 18 (6 x 3) area being pressed ÷ by 36 (2×6+2×3+2×6+2×3) area able to bulge = .5

f2 = .52 = .25 therefore (1 + 2f2) = (1 + (2 x .25)) = 1.5

Using the formula above:

200 = D × 4500 x 1.5

200 = 6750D

200 ÷ 6750 = D

D =.0296 per inch of original thickness (2.9%)

2″ thick pad x .0296 = 0592″ total deflection

Modulus of Elasticity Diagram

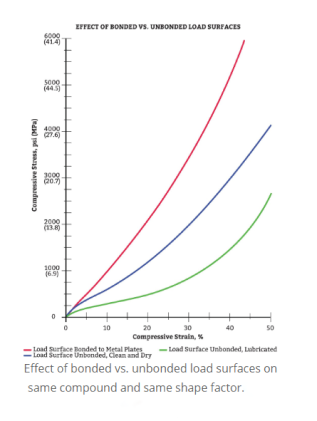

As was mentioned above, the condition of the parts loaded surface, has an effect on deflection. When a part is compressed it wants to expand out laterally and that movement

changes the shape factor. This is particularly noticeable if the surfaces are lubricated. However, if the surfaces are bonded to a substrate such as metal, the shape factor remains the

same. Below is a graph showing the differences in deflection of a bonded part, a dry and clean part and a lubricated part. As you can see, the surface condition of a part can make quite

a difference in deflection.

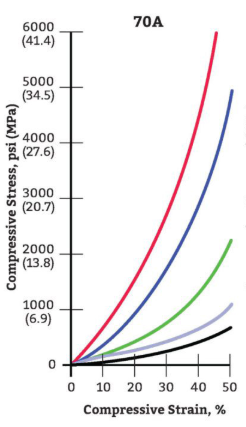

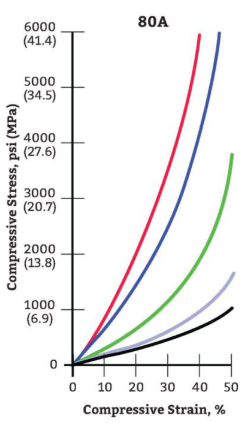

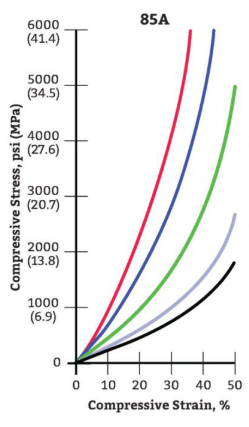

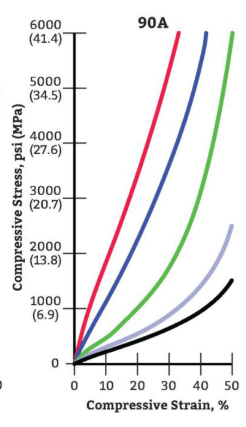

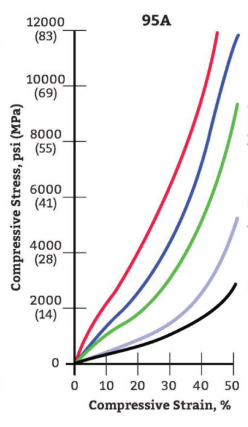

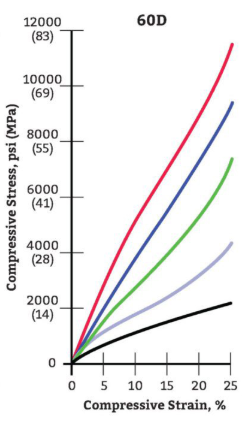

CHARACTERISTICS BY DUROMETER(HARDNESS) AND SHAPE FACTOR

Below are several graphs showing the compression/deflection curve for various shape factors. Each graph is for a different durometer(hardness) of urethane. All samples tested were

bonded to metal surfaces.