Mining & Construction

Industry

Polyurethane plays a crucial role in both mining and construction industries, leveraging its exceptional properties to enhance performance, durability, and efficiency across various applications. In mining, polyurethane’s abrasion resistance makes it invaluable for lining pipes, chutes, and screens, where it protects against wear from abrasive materials like ore and gravel. Its impact resistance is utilized in conveyor belts and equipment linings, reducing damage from heavy loads and impacts, thus extending equipment lifespan. PU’s chemical resistance is essential in environments exposed to corrosive substances, safeguarding equipment integrity and minimizing maintenance downtime. Additionally, its flexibility allows for custom molding into seals, gaskets, and hydrocyclones, optimizing efficiency in material handling and processing operations.

OUR PRODUCTS

Mining Screens

Polyurethane mining screens are integral components in the mineral processing operations of mining sites worldwide. These screens are engineered to withstand the rigors of handling abrasive materials such as coal, iron ore, and aggregates. PU’s inherent abrasion resistance ensures prolonged screen life, reducing downtime and maintenance costs associated with frequent replacements.

One of our standout features of mining screens is their ability to be customized according to specific requirements. Whether for scalping, sizing, or dewatering applications, polyurethane screens can be tailored to fit various screen decks and configurations. This versatility allows us for efficient material separation and improved throughput in mining operations.

Hydrocyclones

Polyurethane hydrocyclones are pivotal in the classification and separation of particles from slurries in mineral processing. Their design optimizes centrifugal force to efficiently separate fine particles from liquids, improving overall process efficiency and yield. In environments where chemical resistance is crucial, such as in the separation of ores and minerals, polyurethane hydrocyclones excel.

Polyurethane hydro cyclones can be tailored to specific particle size ranges and throughput requirements. Their efficient particle separation capabilities contribute to sustainable water management practices on-site. This customization ensures optimal performance in diverse mining applications, from de-sliming to tailings management, enhancing overall operational flexibility and efficiency.

Scraper Blades

Polyurethane scraper blades are indispensable in mining and construction equipment where durability and wear resistance are paramount. These blades excel in cleaning conveyor belts, removing stubborn materials such as coal, gravel, and aggregates without damaging the belt surface. PU’s superior abrasion resistance ensures extended service life and reduced downtime for maintenance.

Unlike traditional metal blades, polyurethane scraper blades are flexible and conform to irregular surfaces, ensuring thorough and efficient cleaning. This flexibility minimizes the risk of material buildup and belt damage, optimizing conveyor performance and throughput.

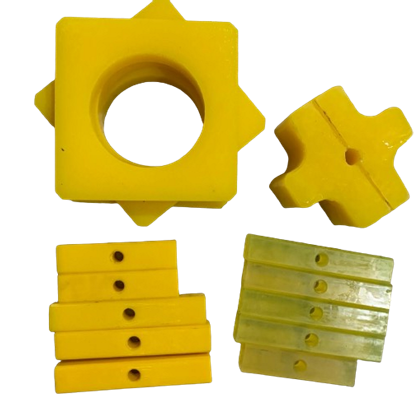

Seals And Couplings

Polyurethane seals and coupling are crucial components in mining and construction equipment, providing effective containment of fluids, dust, and debris. Whether in hydraulic cylinders, pumps, or valves, PU seals prevent leaks and contamination, thereby extending equipment lifespan and reducing maintenance costs

Polyurethane seals can be customized to meet specific performance requirements, ensuring reliable sealing performance in critical applications. Whether for high-pressure environments or extreme temperatures, PU seals offer consistent performance and longevity.

Pu Liners & Bushings

Polyurethane liners and bushings are essential components in mining and construction equipment, reducing friction and wear in mechanical components such as pumps, valves, and conveyor systems. Their self-lubricating properties and resilience to abrasion ensure smooth operation and prolonged service life, minimizing maintenance costs and downtime. PU liners extend the lifespan of equipment by reducing wear and tear caused by abrasive materials such as ore, gravel, and aggregates.

One of the key advantages of polyurethane liners is their ability to be custom molded to fit specific equipment dimensions and configurations. This customization ensures a precise fit and seamless installation, optimizing operational efficiency and minimizing downtime during maintenance.

For any inquiries or questions, please fill out the form below and we will get back to you as soon as possible. info@sashiengineering.com

Phone

Call us directly to speak with our

knowledgeable team.

+91-90358 72283