OIL & GAS

Industry

With the demanding nature of the oil and gas industry, parts that are used in this sector have to be able to meet high standards. The parts must also withstand various conditions, including extreme temperatures, high pressures, and harsh chemicals. Polyurethane parts are often used in the oil and gas industry because they can meet these demanding requirements. Unlike rubber, plastics, and other materials, polyurethane offers hardness versatility, is durable, and is crack and wear-resistant. Urethane or polyurethane also offers high customization as it can be molded in different shapes and measures and can be used in applications typically found in areas that require oil and gas parts.

Due to the extreme durability of urethane material, stability in a downhole environment, and natural resistance to corrosion, pressure, impact, heat, and abrasion, it is the ideal tooling and parts-making material for the oil and gas industry. Because of its natural edge over rubber products and other plastics, urethane parts are slowly becoming the go-to material for many applications in this industry.

Here are some of our polyurethane parts that are used in the oil and gas industry:

Polyurethane Bend Restrictors

Polyurethane bend restrictors are crucial components used to protect flexible pipelines and hoses from excessive bending, fatigue, and damage. They are commonly employed in offshore oil and gas operations, subsea installations, and dredging activities where flexible hoses are subjected to repetitive bending motions. The benefits of polyurethane bend restrictors include:

- Abrasion Resistance: Polyurethane’s robust abrasion resistance ensures prolonged service life even in harsh environments.

- Flexibility: It allows for controlled bending while maintaining structural integrity, reducing stress on hoses and extending their lifespan.

Pipe Pegging Systems

Polyurethane pipe pegging systems are designed to secure and stabilize pipelines on seabed or riverbeds, preventing movement and damage caused by currents, waves, or sediment shifts. These systems typically include polyurethane-coated or encapsulated supports that provide:

- Impact Resistance: Protect pipelines from impacts and external forces during installation and operation.

- Chemical Resistance: Resistant to a wide range of chemicals, polyurethane bend restrictors are suitable for use in corrosive environments.

Pipe and cable clamps

Polyurethane clamps are suitable for offshore and subsea environments where equipment must withstand corrosive seawater, extreme temperatures, and high pressures. They provide secure anchoring and protection for cables and small diameter pipes used in underwater installations, platforms, and marine vessels.

- Corrosion Resistance: Resistant to corrosion from saltwater, chemicals, and environmental exposure, ensuring long-term reliability in offshore and marine environments.

- Easy Installation and Maintenance: Lightweight and easy to install, minimizing downtime during installation or maintenance activities.

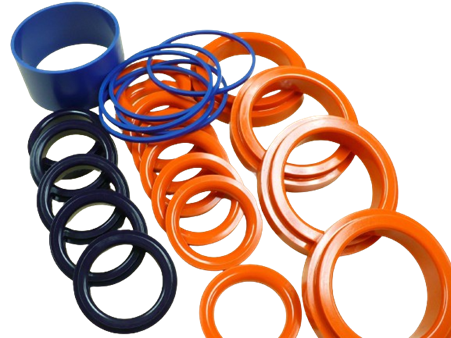

Seals and Gaskets

Polyurethane seals and gaskets are preferred in oil and gas equipment for their resilience and ability to maintain a tight seal under pressure. They are utilized in valves, pumps, and hydraulic systems to prevent leaks and ensure efficient operation. Polyurethane’s resistance to hydrocarbons and other fluids makes it an ideal choice for sealing applications in challenging environments.

- Temperature Stability: Maintaining integrity across a wide range of temperatures, from arctic environments to high-temperature processing conditions.

- Durability: Long service life and resistance to wear and tear, reducing downtime and maintenance frequency.

For any inquiries or questions, please fill out the form below and we will get back to you as soon as possible. info@sashiengineering.com

Phone

Call us directly to speak with our

knowledgeable team.

+91-90358 72283